Specifications Plastic Pellets Making Machine Granulating from Recycled Plastic PP PE

1.recycled plastic

2. CE ISO

3 PP PE PVC Plastic

Plastic Pellets Making Machine Granulating from Recycled Plastic PP PE Wood Plastic Composites

WPC granulating extruder, WPC Pelletizing Machine MACHINE RUNNING VIDEOS ON YOUTUBE

| 4 PE WPC Granulating Machine /Pelletizing machine | http://youtu.be/9uYPR0gpPg0 |

| 4 WPC plastic PE granules/pellets making machine/ wood plastic pelletizing machine line | http://youtu.be/lVywuSYo6Lk |

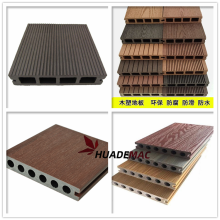

Product Description WPC Products Features 1, New product: The wood-plastic is a new kind of synthetic material through the process of mixing, extruding, calibrating, hauling off and cutting, 2, Material: uses PVC, PP, PE resin or recycled plastic and plant fibre (wood powder, chaff, straw etc.) as raw material. 3, Advantages: This kind of wood-plastic are not only very similar with natural wood in appearance and feel, but also have the same characteristics as wood of excisable, unmatched grip, low bibulous rate, good moisture resistance, mothproof, mildew resistance, good resistance to acid and alkali, anti-corrosion, and it has the feature of fire resistance. It can be sawed, drilled, and planed by the wood working tools. The products are non-toxic, non-polluting, environment-friendly and energy-saved, without formaldehyde, benzene and ammonia and other harmful substances. 4, Product Application: The wood-plastic products are widely used in outdoor floor, close to water construction, balcony, landscape architecture, chairs and benches, fences, interior doors and windows, furniture, etc. Plastic Pellets Making Machine line: granulating from recycled PP PE plastic profiles and plates Wood plastic composites WPC Granulating Extruder machine line include following parts: parallel

Double Screw Extruder, granulate die head, granulate cutting machine, three-grade air supplying system, storage chamber. Double screw extruder and the Auxiliary Machinery

Consistent of auxiliary machinery | Specification |

Material of fan bush | Stainless steel |

Cutting die head | Hot cutting die head |

Cutting lathe | The blade on the cutting lathe ,with speed frequency regulation ,the power of converter : 1.5kw |

Splitter filter | Diameter 800mm,Quantity : 2 sets |

Three fan cooling pipe | Equipped with 3 sets of fan blower, Power : 5.5kw |

Storage | 2m3 |

| Model | Screw

diameter

(mm) | Screw

quantity | L/D

Ratio | Main

Motor

(kw) | Rotating

Speed

(rmp) | Capacity

(kg/hr) |

| SJMS-60 | 60 | 2 | 28-48 | 45-55 | 0-400/600 | 90-200 |

| SJMS-65 | 65 | 2 | 28-48 | 55-75 | 0-400/600 | 150-280 |

| SJMS-72 | 72 | 2 | 28-48 | 90-132 | 0-400/600 | 150-400 |

| SJMS-75 | 75 | 2 | 28-48 | 90-132 | 0-400/600 | 180-450 |

| SJMS-95 | 95 | 2 | 28-48 | 220-280 | 0-300/400 | 450-900 |

Machine's Photos

The total WPC pelletizing machine line:

parallel twin-screw extruder

granulate die head

granule cutting machine

three-grade air supplying system

Final Products: the wood plastic PP PE PVC WPC granules, pellets Processed from recycled plastic profile nad plates

Our Services We provide turnkey project for WPC PP PE profiles and PVC boards, the processing procesure from waste plastic and sawdust to final WPC wood plastic products:

Raw material | PP/PE/PVC + waste wood/rice husk, PVC resin or recycled plastic + plant fibre(sawdust/chaff/straw etc.) |

Final product | Decking, garden railing, garden furniture, pallet, outdoor wall cladding, pergola.... window and doors, ceiling panel, wall siding panel, flooring, furniture board |

Production Process: | Crushing machine→ Milling machine →Mixing machine→ Granulating machine line → Profile Extruding line extruder→ Mold → Product → Calibrating → Hauling off→ Cutting off→ Embossing or polishing machines→ Final product |

Guarantee: 1 year (12 months) counting from the machinery installed and tested by our engineer, free change for the broken spare part for free during guarantee period. Install and test: Professional engineer will be sent to your company to install, test and teach operator at your factory Operation book and video: Operational manual book and video will be sent together with custom clearance documents FAQ Plastic Pellets Making Machine Granulating from Recycled Plastic PP PE, we have these machine lines in stock, welcome your visit to our factory. Any interest, please send me a message, thanks a lot! Contact Person: Sally Mobile: 86-18366236672 Skype: s88sally Email: sally(at)wpcmachinery.com salersally(at)tongsanextruder.com

Contact us if you need more details on Wpc Plastic Pellets Making Machine Granulating Machine Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Plastic Pp Pe Wpc Granulating Machine、Wpc Plastic Pellets Making Machine Granulating Machine Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : WPC granulating extruder

parallel twin-screw extruder

parallel twin-screw extruder  granulate die head

granulate die head  granule cutting machine

granule cutting machine  three-grade air supplying system

three-grade air supplying system  Final Products: the wood plastic PP PE PVC WPC granules, pellets Processed from recycled plastic profile nad plates

Final Products: the wood plastic PP PE PVC WPC granules, pellets Processed from recycled plastic profile nad plates  Our Services We provide turnkey project for WPC PP PE profiles and PVC boards, the processing procesure from waste plastic and sawdust to final WPC wood plastic products:

Our Services We provide turnkey project for WPC PP PE profiles and PVC boards, the processing procesure from waste plastic and sawdust to final WPC wood plastic products: