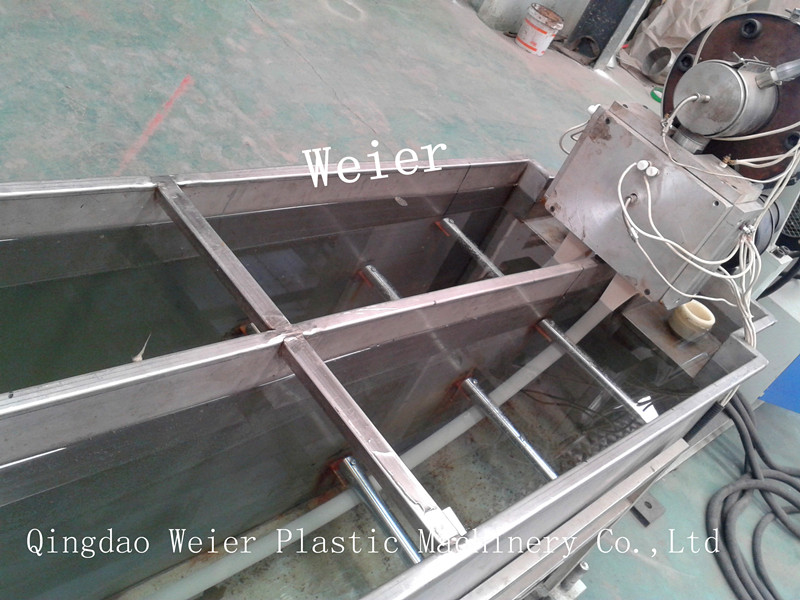

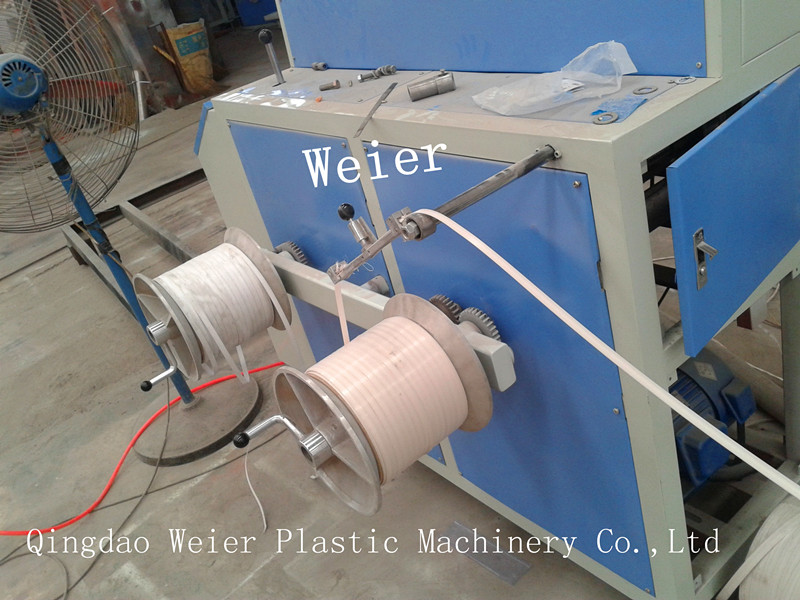

PP Strap Band Production Line

Basic Info

Model No.: SJ-75/30 or SJ-65-25

Product Description

Model NO.: SJ-75/30 or SJ-65-25 Screw: Single-Screw Computerized: Computerized Customized: Customized Inverter: Teco Raw Material: PP Granules or Recycled Transport Package: According to Clients Requirement Origin: Jiaozhou, Shandong, China Product Type: PET Strap Automation: Automatic Certification: CE, ISO9001:2008 Center Height: 1000mm Power(W): 82kw Trademark: Weier Specification: SJ-75/30 or SJ-65-25 HS Code: 84772090 We export our machines to about 40 countries,welcome to visit us.We aim to do long term business with our clients

Product Description PP strapping band line /PP Strap Making Machine line

Video website : http://cloud.video.taobao.com/play/u/1757949571/p/1/e/6/t/1/40460834.mp4

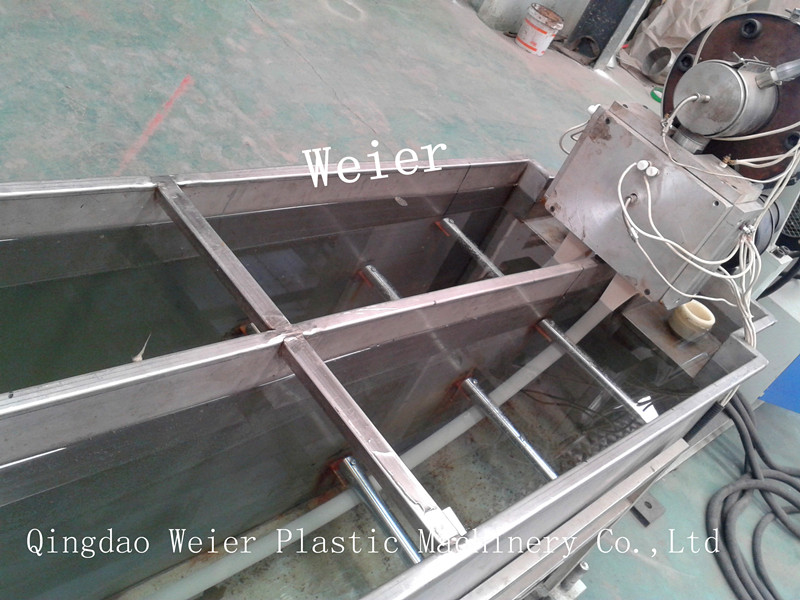

1.capacity:50-180kg/h

2.raw material:PP granules/recycled PP material

3.extruder:Single Screw Extruder

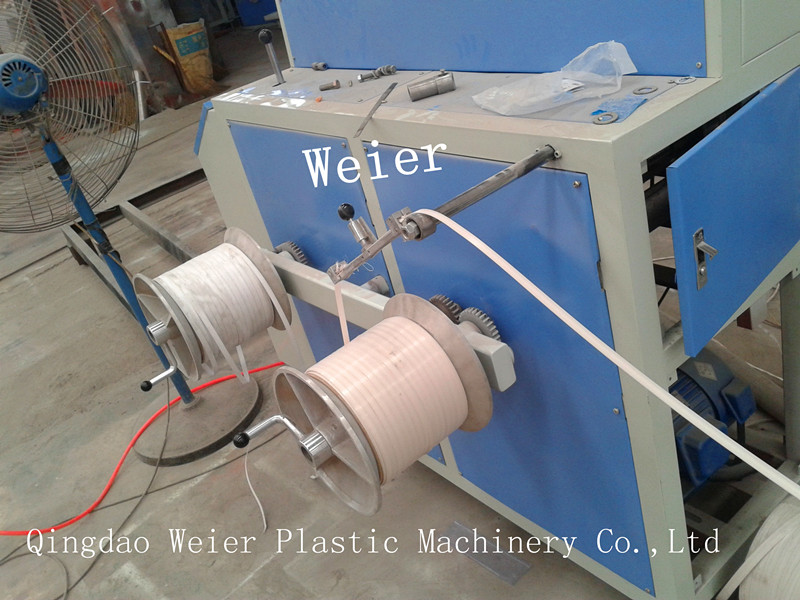

4.product specification:5-19mm (width) 0.5-1.2mm(thickness) or customized

Electrical appliance:

Usage To produce strap band with different size Advantages 1.It is suitable for raw material or recycled material. 2.The strap band is with good tension force, which is widely accepted. 3. The strap band is in uniformity of width, and with precise shape, which can be used on automatic packing machine. 4. Using fully automatic temperature controlling device with chain function. 5.Advanced technology Making the product cost lower than Others by at least 10% 6.Low noise, low power consumption, high efficiency, and long serving life.

Recycled PP can be used

High tension drawing force

The PP strap bands are uniformity in width, precise shape and size can be applied in full automatic strapping machine

With full automatic temperature controling system and automatic alarming system,

Advanced technique makes the product with lower cost.Low power consumption, low noise

The main technique parameter

More details about our services: the supplier provide service manual and maintenance instruction of main electric appliance ,limb , usage manual of equipment We also supply water,electricity,gas of equipment and installation drawing. the supplier is responsible for installation,debug and training, we will realize guarantee of repair; replacement of substandard products within one year. After the machine leaves factory. Fittings of the machine will supply at preferential price after one year .

The seller will send one or two technician to the buyer'plant to debugging,and the tickets ,eating ,transportation and visa fee will bepaid by the buyer ,also including 50USD salary/person /day If anyting intertst ,please contact us at your best convenience,we can produce the overwhelmingtic extrusion Contact person:Victor Phone number:0086-13705422741

"Excellent Quality and Reasonable Price" is our company's quality policy;

"Honest Service and Win-win Cooperation" is our company's core concept.

we offer turn key project, with lifelong after sale service!

we have ready machines in factory for your test and visit! sincerely welcome all friends to visit our factory! Its my honour to do something for you. Contact us if you need more details on PP Strap Band Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Extruder、Extruding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Description PP strapping band line /PP Strap Making Machine line

Video website : http://cloud.video.taobao.com/play/u/1757949571/p/1/e/6/t/1/40460834.mp4

1.capacity:50-180kg/h

2.raw material:PP granules/recycled PP material

3.extruder:Single Screw Extruder

4.product specification:5-19mm (width) 0.5-1.2mm(thickness) or customized

Electrical appliance:

| Inverter | TECO products |

| Breaker,contactor | SIEMENS products |

| buttons | France TE products |

| Temperature-controller | Temperature-controller |

Usage To produce strap band with different size Advantages 1.It is suitable for raw material or recycled material. 2.The strap band is with good tension force, which is widely accepted. 3. The strap band is in uniformity of width, and with precise shape, which can be used on automatic packing machine. 4. Using fully automatic temperature controlling device with chain function. 5.Advanced technology Making the product cost lower than Others by at least 10% 6.Low noise, low power consumption, high efficiency, and long serving life.

Recycled PP can be used

High tension drawing force

The PP strap bands are uniformity in width, precise shape and size can be applied in full automatic strapping machine

With full automatic temperature controling system and automatic alarming system,

Advanced technique makes the product with lower cost.Low power consumption, low noise

The main technique parameter

| Band width | 5-19mm |

| Production linear speed | 120m/min |

| Stretch ratio | 4-9 |

| Max. Output | 50-180kg/h |

More details about our services: the supplier provide service manual and maintenance instruction of main electric appliance ,limb , usage manual of equipment We also supply water,electricity,gas of equipment and installation drawing. the supplier is responsible for installation,debug and training, we will realize guarantee of repair; replacement of substandard products within one year. After the machine leaves factory. Fittings of the machine will supply at preferential price after one year .

The seller will send one or two technician to the buyer'plant to debugging,and the tickets ,eating ,transportation and visa fee will bepaid by the buyer ,also including 50USD salary/person /day If anyting intertst ,please contact us at your best convenience,we can produce the overwhelmingtic extrusion Contact person:Victor Phone number:0086-13705422741

"Excellent Quality and Reasonable Price" is our company's quality policy;

"Honest Service and Win-win Cooperation" is our company's core concept.

we offer turn key project, with lifelong after sale service!

we have ready machines in factory for your test and visit! sincerely welcome all friends to visit our factory! Its my honour to do something for you. Contact us if you need more details on PP Strap Band Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Extruder、Extruding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Sheet Machine

Premium Related Products

Other Products

Hot Products

Weier Swp-360 Plastic Crusher MachineWr-37 Wood Powder Making MachineWater Tank Full Automatic Blow Molding Machine (25L-5000L)Best Price of PVC Ceiling Board Extrusion MachinePVC Crusted Foam Board Production Machine LineCE WPC/PE Floor Panel / Profile Plastic Making Machine (SJSZ-65/132)WPC wood plastic recycle pelleting granulator machinewpc mixing plantPopular Environmental friendly WPC wood plastic door panel extrusion machineWaste Plastic PVC Pulverizer, Plastic Recycling Pulverizer machinePVC add wood powder composite machine/WPC board production machinePVC powder add wood composite production line/WPC board production lineAutomatical Plastic and Wood WPC mixture dosing and mixing machine for polyurethanehigh output wood powder grinding machinePE PP PVC WPC profile production line/WPC profile extrusion linePlastic Wood Deck board sanding machine