PPR Water Hot Cold Pipe Production Line Machine Manufacturing

Basic Info

Model No.: SJ-65/30

Product Description

Model NO.: SJ-65/30 Screw: Single-Screw Computerized: Computerized Customized: Customized Gearbox Material: Qt200 Trademark: WEIER Specification: 11t HS Code: 84472090 Product Type: PPR Pipe Automation: Automatic Certification: CE, ISO9001:2008 Condition: New Material of Screw: 38crmoaia Transport Package: as Per Export Standard Origin: Qingdao, China PPR HOT-COLD WATER PIPE MANUFACTURING MACHINE PRODUCTION LINE

(CE, ISO9001:2008, SGS,ETC) from 16mm-63-160mm

Product Description

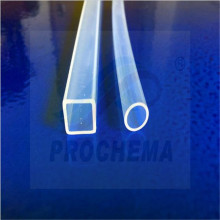

PPR water pipe production machine line ; PPR water pipe extrusion line; ppr hot cold water pipe production line; ppr water pipe manufacturing machine

1.Process for ppr pipe manufacturing machines extrusion line

vacuum feeding machine -hopper dryer- Single Screw Extruder -color code extruder-mould and calibrator vacuum forming machine -cooling tank -haul-off machine -cutting machine- discharging rack.

2.Technical parameter for hdpe pipe manufacturing machines production line:

PPR pipe application and PPR pipe machine composition decription:

PPR pipe machine/Plastic Pipe Machine is used to produce PPR pipes for cold and hot water supply in house. It's composed of vacuum feeding machine, hopper dryer, single screw extruder, mould, mark line co-extruder, vacuum calibration and cooling tank, extended spraying cooling tank, haul off machine, printer, cutter and stack bracket. And for three layers PPR fiber reinforced pipe, there will be also another extruder for middle fiber layer.

PPR pipe can be single layer with mark line extruded by two extruders, or three layers with middle layer glass fiber reinforced extruded by three high effeciency extruders; or four layers ppr glass fiber reinforced pipe,etc

Main advantages of this PPR one layer pipe machine,PPR fiber reinforced three layers, four layers pipe making machine :

1. Barrier type screw, by which the material can get good plasticizing at low temperature but high extrusion output.

2. Barrel with feeding groove, material is 38CrMoAl and nitrogen treated, surface hardness is HRC 65-68, which can has a long use life.

3. Millipore type mould with suitable inner compression ratio which can guarantee to produce high quality PPR pipes.

4. High automatic level. The production line is controlled by PLC(touch screen). All parts, like extruder, haul off unit, cutter etc can be controlled by touch screen synchronously.

Composition of PPR fiber reinforced three layers pipe machine:

FAQ

Q1.How to pay to you?

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

and then pay the 70% balance by TT or irrevocable L/C at sight . Then seller ship the machine.

Q2.How long is the delivery time?

A: For standard machines, it would be 30 days; For non-standard machines and customized machines according

to client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment. We also supply water, electricity, gas of equipment and installation drawing. (2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 50 USD for each engineer will be born by the buyers. We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts. Fittings of the machine will be supplied at preferential price after one year.

Q6.What's your warranty?

We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine arrived in customer's factory (except destroyed by buyers' wrong operation). We guarantee the material of screw & barrel (guarantee without normal abrasion). And half a year for electric parts. Fittings of the machine will supply at preferential price after one year.

Welcome to contact us anytime !

Contact : Jane Zhao

TEL : 0086-158668552549

Contact us if you need more details on Plastic Extruder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Machine、Plastic Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information.

(CE, ISO9001:2008, SGS,ETC) from 16mm-63-160mm

Product Description

PPR water pipe production machine line ; PPR water pipe extrusion line; ppr hot cold water pipe production line; ppr water pipe manufacturing machine

1.Process for ppr pipe manufacturing machines extrusion line

vacuum feeding machine -hopper dryer- Single Screw Extruder -color code extruder-mould and calibrator vacuum forming machine -cooling tank -haul-off machine -cutting machine- discharging rack.

2.Technical parameter for hdpe pipe manufacturing machines production line:

PPR pipe application and PPR pipe machine composition decription:

PPR pipe machine/Plastic Pipe Machine is used to produce PPR pipes for cold and hot water supply in house. It's composed of vacuum feeding machine, hopper dryer, single screw extruder, mould, mark line co-extruder, vacuum calibration and cooling tank, extended spraying cooling tank, haul off machine, printer, cutter and stack bracket. And for three layers PPR fiber reinforced pipe, there will be also another extruder for middle fiber layer.

PPR pipe can be single layer with mark line extruded by two extruders, or three layers with middle layer glass fiber reinforced extruded by three high effeciency extruders; or four layers ppr glass fiber reinforced pipe,etc

Main advantages of this PPR one layer pipe machine,PPR fiber reinforced three layers, four layers pipe making machine :

1. Barrier type screw, by which the material can get good plasticizing at low temperature but high extrusion output.

2. Barrel with feeding groove, material is 38CrMoAl and nitrogen treated, surface hardness is HRC 65-68, which can has a long use life.

3. Millipore type mould with suitable inner compression ratio which can guarantee to produce high quality PPR pipes.

4. High automatic level. The production line is controlled by PLC(touch screen). All parts, like extruder, haul off unit, cutter etc can be controlled by touch screen synchronously.

Composition of PPR fiber reinforced three layers pipe machine:

| item | Equipment |

| 1 | 300KG automatic feeding system |

| 2 | 50kg raw material drying system |

| 3 | SJ-65/33 high efficiency single screw extruder |

| 4 | SJ45/33 high efficiency single screw extruder |

| 5 | SJ25/25 single screw extruder ( for mark line) |

| 6 | mold(including mouth mold, mandril, heating circle) |

| 7 | PPR fiber pipe sizing sleeves (16-63mm) |

| 8 | Vacuum sizing tank |

| 9 | Sprinkling cooling water tank |

| 10 | Twin caterpillar haul off |

| 11 | Planetary dustless high speed cutter |

| 12 | Reversal stacker |

| 13 | Electrical control system |

| 14 | Computer printer (for choice) |

FAQ

Q1.How to pay to you?

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

and then pay the 70% balance by TT or irrevocable L/C at sight . Then seller ship the machine.

Q2.How long is the delivery time?

A: For standard machines, it would be 30 days; For non-standard machines and customized machines according

to client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment. We also supply water, electricity, gas of equipment and installation drawing. (2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 50 USD for each engineer will be born by the buyers. We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts. Fittings of the machine will be supplied at preferential price after one year.

Q6.What's your warranty?

We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine arrived in customer's factory (except destroyed by buyers' wrong operation). We guarantee the material of screw & barrel (guarantee without normal abrasion). And half a year for electric parts. Fittings of the machine will supply at preferential price after one year.

Welcome to contact us anytime !

Contact : Jane Zhao

TEL : 0086-158668552549

Contact us if you need more details on Plastic Extruder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Machine、Plastic Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Pipe Machine

Premium Related Products

Other Products

Hot Products

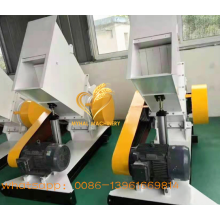

Weier Swp-360 Plastic Crusher MachineWr-37 Wood Powder Making MachineWater Tank Full Automatic Blow Molding Machine (25L-5000L)Best Price of PVC Ceiling Board Extrusion MachinePVC Crusted Foam Board Production Machine LineCE WPC/PE Floor Panel / Profile Plastic Making Machine (SJSZ-65/132)WPC wood plastic recycle pelleting granulator machinewpc mixing plantPopular Environmental friendly WPC wood plastic door panel extrusion machineWaste Plastic PVC Pulverizer, Plastic Recycling Pulverizer machinePVC add wood powder composite machine/WPC board production machinePVC powder add wood composite production line/WPC board production lineAutomatical Plastic and Wood WPC mixture dosing and mixing machine for polyurethanehigh output wood powder grinding machinePE PP PVC WPC profile production line/WPC profile extrusion linePlastic Wood Deck board sanding machine