PVC Crust Foam Board Machine WPC Construction Template Production Line

Basic Info

Model No.: SJ-80/156

Product Description

| Packaging Details: | as export standard for pvc crust foam board machine |

|---|---|

| Delivery Detail: | 60 days pvc crust foam board machine |

Specifications pvc crust foam board machine

1.professional technique,high output

2.w=1220mm,t=3-30mm

3.pvc wpc board

4.ready machine lines.

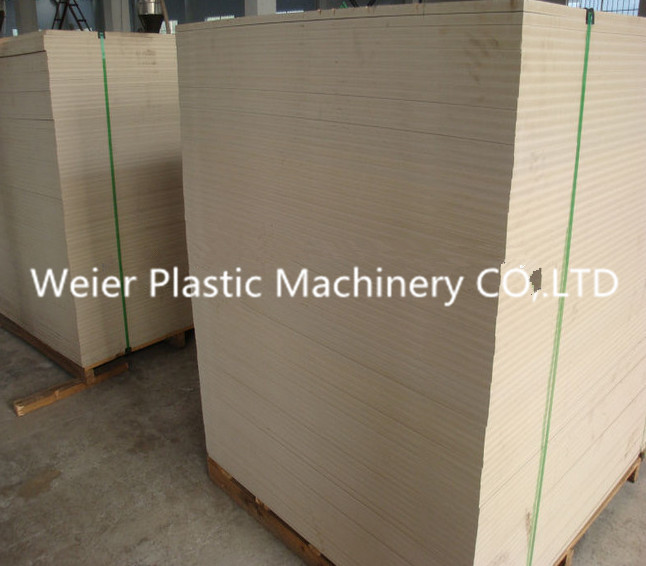

PVC WPC CELUKA SKINNING FOAM BOARD PRODUCTION LINE; WPC CRUST FOAM BOARD MACHINE; WPC CONSTRUCTION TEMPLATE BOARD PRODUCTION LINE instruction of wood plastic pvc wpc foam board/ construction templates: The wood-plastic construction template is a new type of template to replace steel templates and bamboo plastic sheet. With light weight, impact strength, convenient assembling, high turnover, smooth surface, no moisture, no mildew, acid, does not crack, WIDTH, less joints, sawing, nailing, can be processed into any length, and many other advantages. Can be repeatedly recycled more than 20 times, the price is far lower than the current construction industry to use bamboo template, and has excellent flame retardant properties, from the self-extinguishing of fire, smoke-free, without any gas. The new generation of safe green energy-saving products. 1) Size: depends on client 2) Color: yellow, strawberry red, brown, brownish red, silver gray, dark..6 colors available. 3) Material: 30% HDPE or PVC(Grade A Recycled ) 60% bamboo/wood fiber (Professionally treated dry bamboo/wood fiber) 10% chemical additives. (wood texture strong, resistant to abrasion, impact resistance, high-density, waterproof, moisture-proof, anti-termite, easy installation.etc.) 4 )Main feature: 1. High recyclable, eco-friendly, saving forest resources 2. with the look of the natural wood but less timber problems 3. Moisture/Water resistant, less rotten, proven under salt water condition 4. Barefoot friendly, anti-slip, less cracking, less warping, 5. Requires no painting, no glue, low maintenance 6. Weather resistant, suitable from minus - 40 to 60 centigrade degree 7. Well done of Termites, insects, and moldy-proof 8. Available in different colors 9. Easy to install and clean Parameter of wpc pvc construction template machinery

Items | Requirements |

Product size | 1220mm width, length can cut at any length |

Product thickness | 5-20mm (ABA three layer, B is foamed layer, A is unfoaming layer) |

Product application | Furniture board, kitchen cabinet, construction formwork |

Density | 0.45-0.8ton/m3 |

Raw material | PVC+wood+caco3+chemical additives |

Finishing surface | Laminating, hot stamping, printing, painting |

Production capacity | 250-400kg/h |

| 1. SJSZ92/188 or SJSZ 80/156 conical twin screw extruder | one set |

| 2.Mold for door--600,800, 900,1000,1200*(30mm ) | one set |

| 3.Vacuum calibration table | one set |

| 4.Pair Roll Haul Off Unit | one set |

| 5.Cutting uint | one set |

| 6.Conveying unit | one set |

| 7.Electric cabinet | one set |

| 8.Spare parts list | one set |

WPC construction templates have advantages compare with the traditional building templates

1.Environmental protection. Whether timber resources or steel resources, both of them are non-renewable resources, the government will strict controlling the use of them via rise the timber and steel price. the raw materials of the wood-plastic building templates is recycled waste plastics and recycled wood materials. Those recycled materials is not including formaldehyde harmful chemicals, the government will promote it and have a good market in the near future.

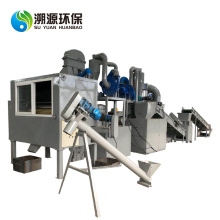

2.Recyclability. The traditional building templates can not recycle it after use it, and will become solid waste, which will increase the environmental pollution. The wood-plastic building templates can be recycled, i.e. the damaged wood-plastics building waste can be crushed and as recycled materials use again.

3.Recycled times. Traditional wooden templates only can recycle three or four times, but the wood-plastic building templates can recycle 25 to 28 times

4.Intensity. Intensity of Wood-plastics building templates is 8-10 times compare with the traditional ones, and the wood-plastic templates can fall from the 3 to 4 meters height without damage and deformation. Also have the advantages of non-bibulous, non-stratification and not easy remolding

5.Other features: same as the traditional templates can saw, Nail and drill. And it is easy for construction workers installation and integration. Also have the advantage of flame retardant, anti-corrosive and moth-proof and can adapt to the temperature change range, eliminates the unnecessary risk of loss and potentially dangerous. In recent years, wood-plastic templates factories invest a large amount of funds and employ high-class workers, after long time research and experiments, got the breakthrough in manufacturing wood-plastic machines and technology, succeed in producing the machines and put it in operation and extrude the high quality wood plastic building templates. Every day output is 500square meters(thickness12-15mm).so get the leading position in the industry field. Contact us if you need more details on PVC Crust Foam Board Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about WPC Construction Template Production Line、Plastic Template Board Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Board Machine

Premium Related Products