XPS plastic Insulation Foam Board Extrusion Machine From 15 Years Factory

Basic Info

Model No.: SHJ85/40

Product Description

Model NO.: SHJ85/40 Plastic Processed: XPS Feeding Mode: One Feed Screw: Twin-Screw Screw Channel Structure: Deep Screw Automation: Automatic Total Power: 300kw Splitting Machine: Automatic Trademark: weier Specification: 48*4*5 HS Code: 84772090 Type: Sheet Extruder Product Type: Extrusion Molding Machine Assembly Structure: Integral Type Extruder Engagement System: Intermeshing Exhaust: Exhaust Computerized: Computerized Output: 350kg/H Scrfp Edge: Self-Motion Adjustable Transport Package: Nude Packing Origin: Shandong XPS Foam Board Extrusion Line ---Produce Application---XPS foamed board produced by this line, also named as polystyrene extrusion plastic board (XPS for short) has a perfect closed-pore alveolate structure Density, water absorption, coefficient of heat conducting and the coefficient of steam pervasion are all lower than those of other board heat preservation materials Strong intensity, light material, airtight, anti-corrosion, aging resistance, low cost Widely used in the fields of heat preservation and heat insulation in the construction industry, frost resistance of the highway, railway, airport, square and household fitment Is the generally acknowledged and the best heat preservation material in the market at present.

---Equipment list---

We have already Feasibility report,Market cost analysis report,Technical drawing,Detailed quotation.Write to me,you'll get professional solution!

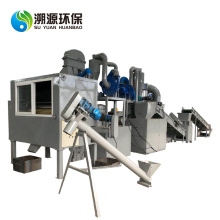

---Pictures of our machines and products---

---Packing & Delivery---

---Exhibition Certificate & Shipping---

---Contact us---

Contact us if you need more details on XPS Foam Board Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about XPS Foam Board Extruder、XPS Foamed Board Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on XPS Foam Board Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about XPS Foam Board Extruder、XPS Foamed Board Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Model | Unit | XPS-135/150 | XPS-150/170 | XPS-170/200 | |||

| Extruder | 135/150 | 150/170 | 170/200 | ||||

| Heating power | kw | 52 | 52 | 58 | 68 | 78 | 100 |

| Driving motor power | kw | 75 | 90 | 90 | 110 | 110 | 132 |

| Thickness of board | mm | 20,25,30,40,50,60,75,80 | 20,25,30,40,50,60,75,100 | 40,50,60,75,100,120 | |||

| Width of board | mm | 600,900 | 600,900,1200 | 600,900,1200 | |||

| Length of board | mm | 1200,1250,2450,2500 | |||||

Edge of board | SS flat head(SL lap joint, RC rain groove) | ||||||

| Output | kg/h | 280-320 | 300-360 | 380-500 | |||

| Install capacity | kw | 300 | 380 | 400 | |||

| Dimension | mm | 35000*10000*4000 | 35000*10000*4000 | 35000*10000*4000 | |||

| Total weight | T | 28 | 33 | 33 | |||

| 1 | Automatic material-feeding system and 200L mixing machine |

| 2 | The first extrusion system |

| 3 | Foaming agent-injecting system |

| 4 | Hydraulic mesh-change system |

| 5 | The second extrusion system |

| 6 | Extrusion machine die and mould |

| 7 | Calibrating device |

| 8 | The first hauling system |

| 9 | Transmitting and cooling system |

| 10 | The second hauling system |

| 11 | Longitudinal cutting system |

| 12 | Transverse cutting system |

| 13 | The whole electrical control system |

---Pictures of our machines and products---

---Packing & Delivery---

---Exhibition Certificate & Shipping---

---Contact us---

Contact us if you need more details on XPS Foam Board Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about XPS Foam Board Extruder、XPS Foamed Board Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on XPS Foam Board Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about XPS Foam Board Extruder、XPS Foamed Board Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Plastic Board Machine

Premium Related Products

Other Products

Hot Products

Weier Swp-360 Plastic Crusher MachineWr-37 Wood Powder Making MachineWater Tank Full Automatic Blow Molding Machine (25L-5000L)Best Price of PVC Ceiling Board Extrusion MachinePVC Crusted Foam Board Production Machine LineCE WPC/PE Floor Panel / Profile Plastic Making Machine (SJSZ-65/132)WPC wood plastic recycle pelleting granulator machinewpc mixing plantPopular Environmental friendly WPC wood plastic door panel extrusion machineWaste Plastic PVC Pulverizer, Plastic Recycling Pulverizer machinePVC add wood powder composite machine/WPC board production machinePVC powder add wood composite production line/WPC board production lineAutomatical Plastic and Wood WPC mixture dosing and mixing machine for polyurethanehigh output wood powder grinding machinePE PP PVC WPC profile production line/WPC profile extrusion linePlastic Wood Deck board sanding machine