WPC board making machine/Wood plastic composite WPC furniture board,construction board making machine

Basic Info

Model No.: SJMS80/156,SJMS92/188

Product Description

WPC Board Making Machine/WPC board production line Wood plastic composite WPC furniture board,construction board making machine  Material:PVC resin or recycled plastic and plant tibre(wood powder/chaff/straw etc) ?v=gfqxK0GaY8k Wood milling machine ?v=WaT7UVo1TJs WPC PVC board machine ?v=5d56jeTxbxU WPC PVC foam skirting board machine ?v=IuWMDkfgWr8 PVC foam board machine

Material:PVC resin or recycled plastic and plant tibre(wood powder/chaff/straw etc) ?v=gfqxK0GaY8k Wood milling machine ?v=WaT7UVo1TJs WPC PVC board machine ?v=5d56jeTxbxU WPC PVC foam skirting board machine ?v=IuWMDkfgWr8 PVC foam board machine

The features of WPC making machinery 1)This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber,and the material is 90% of waste plastic and waste natural fiber. 2)With scientific and reasonable technology,the machine has high efficiency and runs stably 3)The parallel twin screw extruder is used to mix the wood and plastic,and get good homogeneous melt. 4)This is one step WPC extrusion technology,which saves energy 5)This production line can produce wpc products of different specifications only to change mold. 6)Imported PLC automatic control. Product Description EXTRUDER There are two choices for you: SJMS 80/156 Conical Double Screw Extruder SJMS 92/188 Conical double screw extruder Die head and mould T type mould Mould lip heating mode: Oil heating,equipped wiht mould temperature controller

Die head and mould T type mould Mould lip heating mode: Oil heating,equipped wiht mould temperature controller  Vacuum Sizing Platform Material : stainless steel The adjustment mode of stock mould height: Pneumatic

Vacuum Sizing Platform Material : stainless steel The adjustment mode of stock mould height: Pneumatic  Hual Off Machine Clamp mode: pneumatic clamp

Hual Off Machine Clamp mode: pneumatic clamp  Equipped with sider trimming cutter

Equipped with sider trimming cutter

Equipped with dust absorption device,air blower collection Cutting Machine & Stacker Automatic cycle cutting,meter counting Material of bracket roller: stainless steel

Cutting Machine & Stacker Automatic cycle cutting,meter counting Material of bracket roller: stainless steel  Electrical Control Parts

Electrical Control Parts

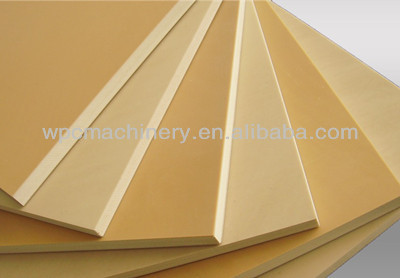

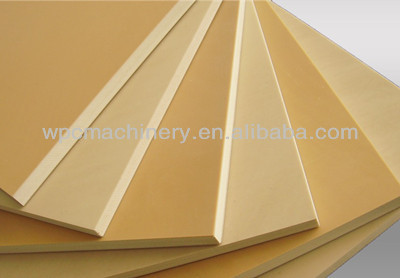

Product Product Thickness: 3mm-30mm Color: accroding to your requirement  Packaging & Shipping The machine wil be packed by bubble wrap and stretch film. Packed machine will be fixed by iron wire and belt in the container

Packaging & Shipping The machine wil be packed by bubble wrap and stretch film. Packed machine will be fixed by iron wire and belt in the container  Our Services Pre-sale services: 1 Provide the free consultation of the machine 2 Provide the standard device and the flow chart 3 According to the clients’ special requirement, offering the reasonable plan and free design helping to select the machine 4 Welcome to visit our factory or the domestic clients’ factory. Services during the sales: 1 Help client design the factory and offering professional advice, free engineering drawing for the factory layout. 2 Inspect the machine before leaving the factory. 3 Send our experienced workers and engineer to your factory for installing and adjusting all the machine 4 Train the first-line operator. 5 Provide the basic formula After sale services: 1 One year warranty 2 24 hours online service 3 Engineers available to service machinery overseas 4 Provide technical exchanging Our company can supply total production line,including wood milling machine,PVC milling machine,Mixer,PVC foam board machine, Chiller,Air compressor,Plastic Crusher,etc. Company Information

Our Services Pre-sale services: 1 Provide the free consultation of the machine 2 Provide the standard device and the flow chart 3 According to the clients’ special requirement, offering the reasonable plan and free design helping to select the machine 4 Welcome to visit our factory or the domestic clients’ factory. Services during the sales: 1 Help client design the factory and offering professional advice, free engineering drawing for the factory layout. 2 Inspect the machine before leaving the factory. 3 Send our experienced workers and engineer to your factory for installing and adjusting all the machine 4 Train the first-line operator. 5 Provide the basic formula After sale services: 1 One year warranty 2 24 hours online service 3 Engineers available to service machinery overseas 4 Provide technical exchanging Our company can supply total production line,including wood milling machine,PVC milling machine,Mixer,PVC foam board machine, Chiller,Air compressor,Plastic Crusher,etc. Company Information  If you are interested in our machine,please contact me at any time.

If you are interested in our machine,please contact me at any time.  Contact us if you need more details on Wpc Board Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Plastic Composite Board Making Machine、Wpc Board Making Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Wpc Board Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Plastic Composite Board Making Machine、Wpc Board Making Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Material:PVC resin or recycled plastic and plant tibre(wood powder/chaff/straw etc) ?v=gfqxK0GaY8k Wood milling machine ?v=WaT7UVo1TJs WPC PVC board machine ?v=5d56jeTxbxU WPC PVC foam skirting board machine ?v=IuWMDkfgWr8 PVC foam board machine

Material:PVC resin or recycled plastic and plant tibre(wood powder/chaff/straw etc) ?v=gfqxK0GaY8k Wood milling machine ?v=WaT7UVo1TJs WPC PVC board machine ?v=5d56jeTxbxU WPC PVC foam skirting board machine ?v=IuWMDkfgWr8 PVC foam board machine The features of WPC making machinery 1)This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber,and the material is 90% of waste plastic and waste natural fiber. 2)With scientific and reasonable technology,the machine has high efficiency and runs stably 3)The parallel twin screw extruder is used to mix the wood and plastic,and get good homogeneous melt. 4)This is one step WPC extrusion technology,which saves energy 5)This production line can produce wpc products of different specifications only to change mold. 6)Imported PLC automatic control. Product Description EXTRUDER There are two choices for you: SJMS 80/156 Conical Double Screw Extruder SJMS 92/188 Conical double screw extruder

Die head and mould T type mould Mould lip heating mode: Oil heating,equipped wiht mould temperature controller

Die head and mould T type mould Mould lip heating mode: Oil heating,equipped wiht mould temperature controller  Vacuum Sizing Platform Material : stainless steel The adjustment mode of stock mould height: Pneumatic

Vacuum Sizing Platform Material : stainless steel The adjustment mode of stock mould height: Pneumatic  Hual Off Machine Clamp mode: pneumatic clamp

Hual Off Machine Clamp mode: pneumatic clamp  Equipped with sider trimming cutter

Equipped with sider trimming cutterEquipped with dust absorption device,air blower collection

Cutting Machine & Stacker Automatic cycle cutting,meter counting Material of bracket roller: stainless steel

Cutting Machine & Stacker Automatic cycle cutting,meter counting Material of bracket roller: stainless steel  Electrical Control Parts

Electrical Control Parts | Frequency converter | SIEMENS OR ABB |

| Contactor | France Schneider |

| Temperature Controller | Japan Omron |

Packaging & Shipping The machine wil be packed by bubble wrap and stretch film. Packed machine will be fixed by iron wire and belt in the container

Packaging & Shipping The machine wil be packed by bubble wrap and stretch film. Packed machine will be fixed by iron wire and belt in the container  Our Services Pre-sale services: 1 Provide the free consultation of the machine 2 Provide the standard device and the flow chart 3 According to the clients’ special requirement, offering the reasonable plan and free design helping to select the machine 4 Welcome to visit our factory or the domestic clients’ factory. Services during the sales: 1 Help client design the factory and offering professional advice, free engineering drawing for the factory layout. 2 Inspect the machine before leaving the factory. 3 Send our experienced workers and engineer to your factory for installing and adjusting all the machine 4 Train the first-line operator. 5 Provide the basic formula After sale services: 1 One year warranty 2 24 hours online service 3 Engineers available to service machinery overseas 4 Provide technical exchanging Our company can supply total production line,including wood milling machine,PVC milling machine,Mixer,PVC foam board machine, Chiller,Air compressor,Plastic Crusher,etc. Company Information

Our Services Pre-sale services: 1 Provide the free consultation of the machine 2 Provide the standard device and the flow chart 3 According to the clients’ special requirement, offering the reasonable plan and free design helping to select the machine 4 Welcome to visit our factory or the domestic clients’ factory. Services during the sales: 1 Help client design the factory and offering professional advice, free engineering drawing for the factory layout. 2 Inspect the machine before leaving the factory. 3 Send our experienced workers and engineer to your factory for installing and adjusting all the machine 4 Train the first-line operator. 5 Provide the basic formula After sale services: 1 One year warranty 2 24 hours online service 3 Engineers available to service machinery overseas 4 Provide technical exchanging Our company can supply total production line,including wood milling machine,PVC milling machine,Mixer,PVC foam board machine, Chiller,Air compressor,Plastic Crusher,etc. Company Information  If you are interested in our machine,please contact me at any time.

If you are interested in our machine,please contact me at any time.  Contact us if you need more details on Wpc Board Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Plastic Composite Board Making Machine、Wpc Board Making Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Wpc Board Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Plastic Composite Board Making Machine、Wpc Board Making Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : WPC Plate extruder > Other WPC Plate extruder

Premium Related Products

Other Products

Hot Products

Weier Swp-360 Plastic Crusher MachineWr-37 Wood Powder Making MachineWater Tank Full Automatic Blow Molding Machine (25L-5000L)Best Price of PVC Ceiling Board Extrusion MachinePVC Crusted Foam Board Production Machine LineCE WPC/PE Floor Panel / Profile Plastic Making Machine (SJSZ-65/132)WPC wood plastic recycle pelleting granulator machinewpc mixing plantPopular Environmental friendly WPC wood plastic door panel extrusion machineWaste Plastic PVC Pulverizer, Plastic Recycling Pulverizer machinePVC add wood powder composite machine/WPC board production machinePVC powder add wood composite production line/WPC board production lineAutomatical Plastic and Wood WPC mixture dosing and mixing machine for polyurethanehigh output wood powder grinding machinePE PP PVC WPC profile production line/WPC profile extrusion linePlastic Wood Deck board sanding machine